High-Quality Fluoroelastomers Withstand Harsh Underhood Environments

Increasingly stringent global emission control and fuel economy regulations are requiring automakers to rethink how they design cars. Because turbochargers increase an internal combustion engine's efficiency and power output by forcing extra compressed air into the combustion chamber, their use has increased dramatically.

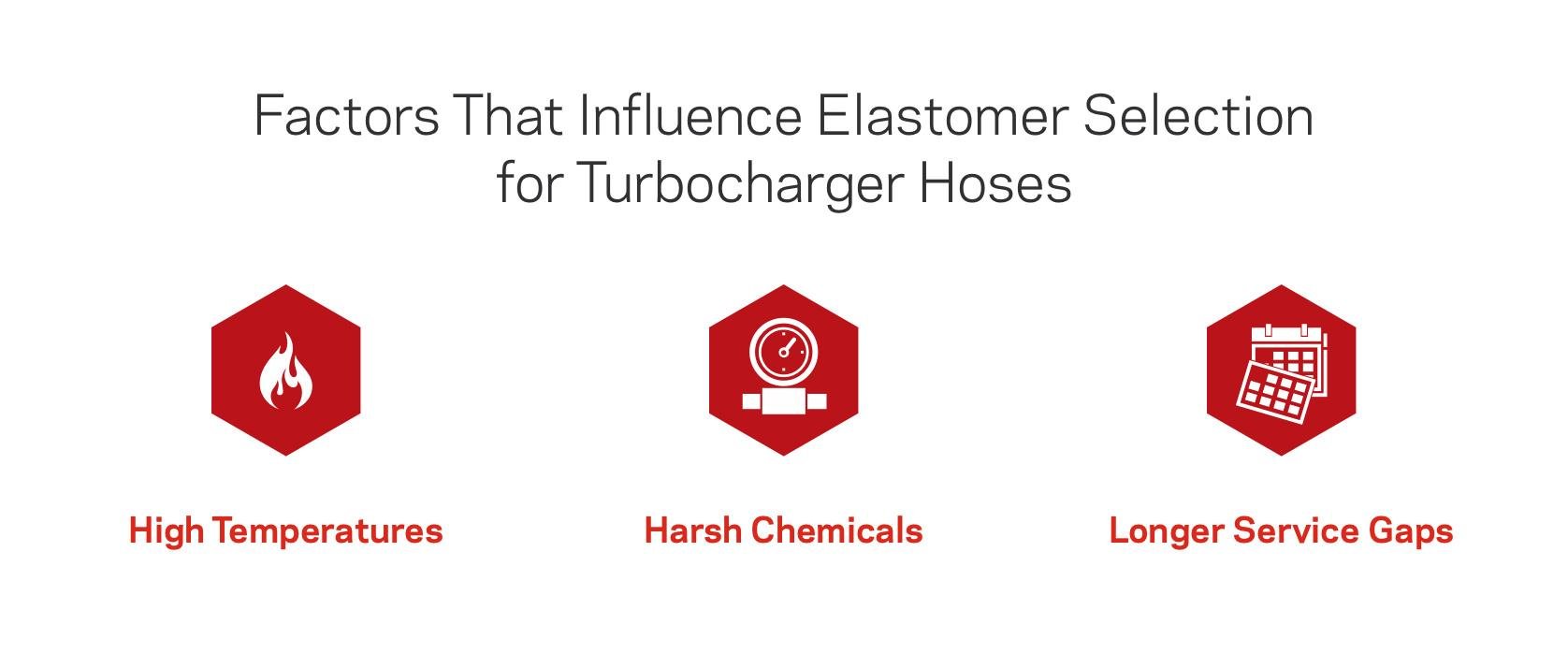

These automotive changes have, however, affected the conditions to which turbocharger hoses are exposed:

- Harsh chemicals

- Synthetic oils

- Auto fuel vapors

- Acidic exhaust gas condensates

These demanding conditions significantly impact material performance and lifespan making the choice of elastomer material critical. Standard elastomers simply can't withstand the tough demands of these environments.

This white paper explains how using high-quality fluoroelastomers can extend component life thanks to their exceptional durability, superior quality, ability to perform well in extreme operating chemicals, and resistance to chemicals.

Download this white paper to learn how selecting the right elastomer improves the high temperature durability of automobile turbocharger hoses.